Ink density reports to save time and money

Newspaper publishers and commercial printers are facing ever-increasing material; labor and energy costs even as competitive pressures limit the opportunity to re-cover those costs through price increases.

Add to that the fact that in most market segments, run lengths are decreasing and make-readies per day are increasing. The bottom line is a serious squeeze on profits.

In response, publishers and commercial printers are examining the deployment of automatic ink presetting systems that can be used to set color quickly, and thus compress the amount of ink and press time wasted during make-readies.

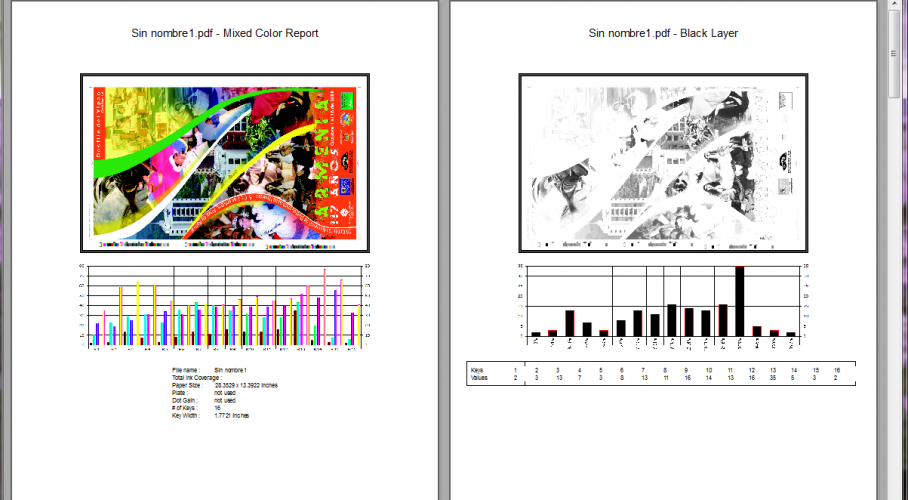

There must be a predictable relationship between the percentage of dot coverage on the plate and the ink key setting required to supply the correct volume of ink. The first step is to determine the coverage of the plate by using various brands of densitometers.

The second step is to determine the dot gain achieved by printing the normalized correction in the first step on various types of paper.

Once this is done, you can use a tool such as Ink Ready to properly calculate the ink density levels of your job, in order to speed up setup time at the press. It reduces paper and ink waste since the target quality on paper is reached almost immediately